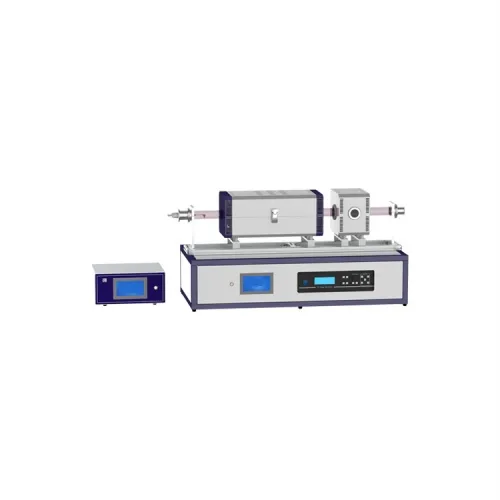

| Two heating zone tube furnace |

Product model |

HS-O1200-50IIT |

| Furnace tube material |

High purity quartz |

| Tube diameter |

50mm |

| Furnace tube length |

1200mm |

| Furnace chamber length |

440mm |

| Heating zone length |

200mm+200mm |

| Operating temperature |

0~1100℃ |

| Temperature control accuracy |

±1℃ |

| Temperature control mode |

30 or 50 segment program temperature control |

| Display mode |

HD full color LCD touch screen |

| Sealing method |

304 stainless steel vacuum flange |

| Power supply |

AC: 220V 50/60Hz 2.5kw |

| RF output system |

Power range |

0~500W adjustable |

| working frequency |

13.56MHz+0.005% |

| Working mode |

Continuous output |

| Matched impedance mode |

It can be matched, and the glow is evenly distributed throughout the furnace tube |

| Power stability |

≤2W |

| Normal working reflected power |

≤3W |

| Amplified reflected power |

≤70W |

| Harmonic component |

≤-50dBc |

| Overall efficiency |

≥70% |

| Power Factor |

≥90% |

| Supply voltage/frequency |

Single-phase AC (187V~153V) frequency 50/60Hz |

| Control mode |

Internal control/PLC analog quantity/RS232/485 communication |

| Power protection settings |

DC over current protection, power amplifier over temperature protection, reflected power protection |

| Cooling method |

Forced air cooling |

| Glow zone |

Under Ar, the radio frequency power supply and the coil cooperate with the glow to fill the furnace tube |

| Evaporation boat |

Working temperature |

1300℃ |

| Evaporation source |

Tungsten wire basket, optional tapered alumina crucible |

| Thermocouple |

S type thermocouple |

| Working current |

≤30A |

| Max. power |

500W |

| Gas delivery system |

Flowmeter |

Four-channel mass flowmeter |

| Flow range |

MFC1 range: 0~200sccm MFC2 range: 0~200sccm

MFC3 range: 0~500sccm MFC4 range: 0~500sccm

Corresponding to gases H2, CH4, N2, Ar.

|

| Measurement accuracy |

±1.5%F.S |

| Repeatability |

±0.2%FS |

| Linear accuracy |

±1%F.S. |

| Response time |

≤4s |

| Work pressure |

-0.15Mpa~0.15Mpa |

| Flow control |

LCD touch screen control, digital display, each channel gas contains needle valve for individually control. |

| Intake Interface |

It can be connected with 1/4NPS or 6mm outer diameter stainless steel pipe |

| Outlet Interface |

It can be connected with 1/4NPS or 6mm outer diameter stainless steel pipe |

| Connection method |

Double ferrule connector |

| Operating temperature |

5~45℃ |

| Gas premix |

Equipped with gas premixing device |

| Exhaust system |

Product model |

HS-GZK103-A |

| Molecular pump |

Turbomolecular pump |

| Backing pump |

Two-stage rotary vane pump |

| Pumping rate |

Molecular pump: 600L/S |

Comprehensive pumping performance: 30 minutes vacuum can reach: 5×10E-3Pa |

| Rotary vane pump: 1.1L/S |

| Ultimate vacuum |

5×10E-4Pa |

| Pumping port |

KF40 |

| Exhaust interface |

KF16 |

| Vacuum measurement |

Compound vacuum gauge |