| Input Power |

●Single phase 220 VAC, 50 / 60 Hz

●1000 W (including vacuum pump and water chiller) |

| Power Source |

●13.5 MHz, 100 W RF generator with manual matching is included and connected to the sputtering heads

●Load range: 0 - 80 adjustable. Tuning range: -200j - 200j adjustable

●The rotatable switch can activate one sputtering head at a time. Sputtering heads can be switched "in the plasma" (no breaking of vacuum and plasma during a multilayer process)

●With a DC power supply, the coater can be easily modified into 1" DC sputtering sources for metallic film deposition, enabling three DC, one RF / two DC, and two RF / one DC sputtering head configurations

●Optional 300 W auto-match RF generator is available at extra cost |

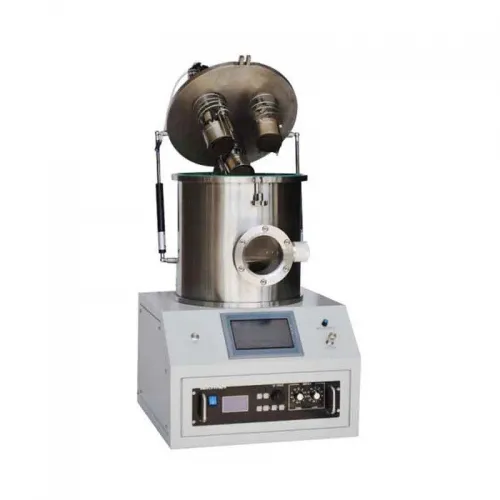

| Magnetron Sputtering Head |

●Three 1" magnetron sputtering heads with water cooling jackets are included and inserted into quartz chamber via quick clamps

●RF cable replacement can be purchased at CYKY

●One manually operated shutter is built on the flange

●One 10 L/min digitally controlled recirculating water chiller is included for cooling sputtering heads |

| Sputtering Target |

●Target size requirement: 1" diameter x 1/8" thickness max

●Sputtering distance range: 50 - 80 mm adjustable

●Sputtering angle range: 0 - 25° adjustable

●1" diameter Cu target and Al2O3 target are included for demo testing

●Various oxide 1" sputtering targets are available upon request at extra cost

●For target bonding, 1 mm and 2 mm copper backing plates are included. |

| Vacuum Chamber |

●Vacuum chamber: 256 mm OD x 238 mm ID x 276 mm Height, made of high purity quartz

●Sealing flange: 274 mm Dia. made of Aluminum with high-temperature silicone O-ring

●Stainless steel shield cage is included for 100% shielding of RF radiation from the chamber

●Max vacuum level: 1.0E-5 Torr with optional turbo pump and chamber baking |

| Sample Holder |

●Sample holder is a rotatable and heatable stage made of ceramic heater with stainless steel cover

●Sample holder size: 50 mm Dia. for. 2" wafer max

●Rotation speed: 1 - 10 rpm adjustable for uniform coating

●The holder temperature is adjustable from RT to 600 °C max (5 min max at 600 °C; 2 hr max at 500 °C) with accuracy +/- 1.0 °C via a digital temperature controller |

| Vacuum Pump |

●KF40 vacuum port is built in for connecting to a vacuum pump.

●Vacuum level: 1.0E-2 Torr with included dual stage mechanical pump

1.0E-5 Torr with optional turbo pump |

| Size |

540 mm L x 540 mm W x 1000 mm H |

| Net Weight |

60 kg |

| Compliance |

CE approval |

| Warranty |

One years limited warranty with lifetime support |